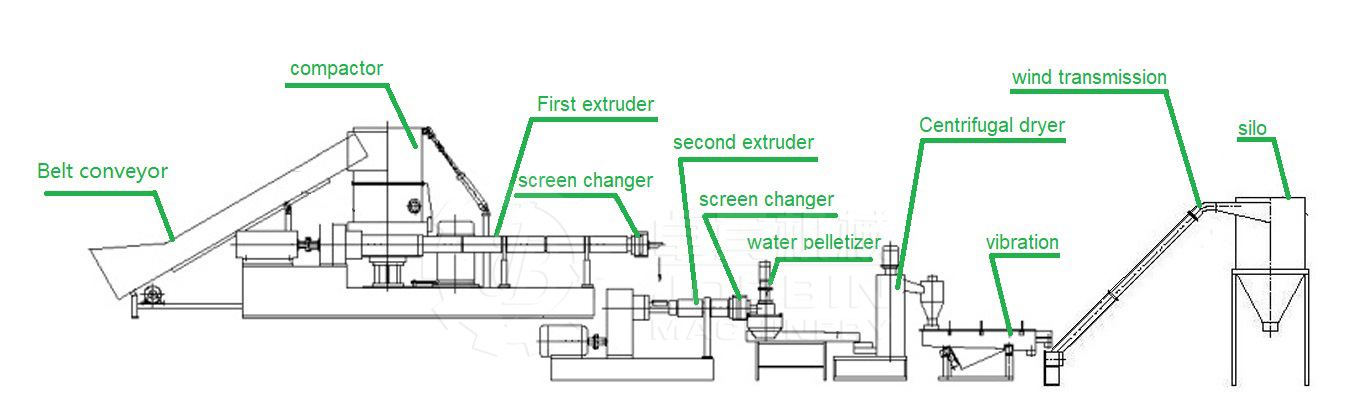

Upto different material’s character, we will design the extruder with defferent special mixing geometry, so that the mateial can be melted perfect. With the years of technology R & D on compactor(agglomerate), our compactor with these advantage:

1. Counter current technology: Hight process stability thorugh improved material intake ensures constantly high output over a considerably broader temperature rang.

2. Smart Start: Remarkably easy operate thanks to logical, clearly structured and simplified handing and ultramodern ergonomiic touchscreen disply.

3. Save:Lower specific energy requirements thanks to a complete package featuring design and process engineering measures including the new direct drive for the extruder screw.