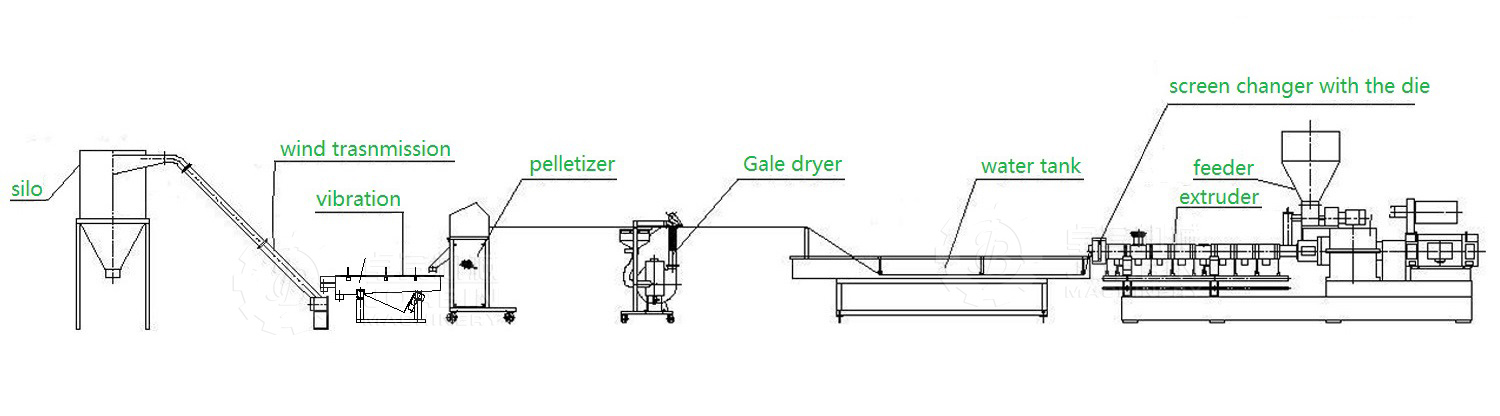

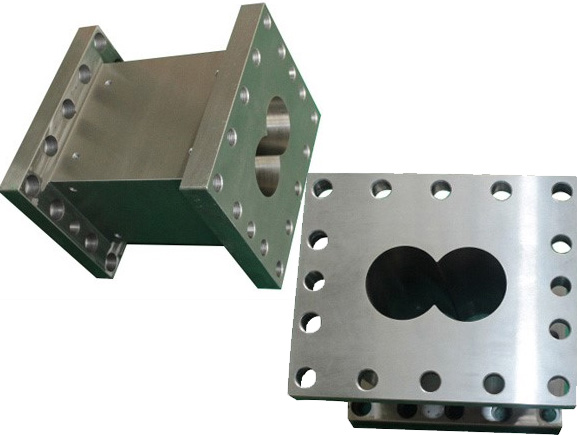

This PET bottle flakes granulation machine has excellent performance,Special design of screw combination with special design gearbox, the machine won’t break IV too much, and customer also can add a Tackifier to improve the IV to confrim the quality of material.

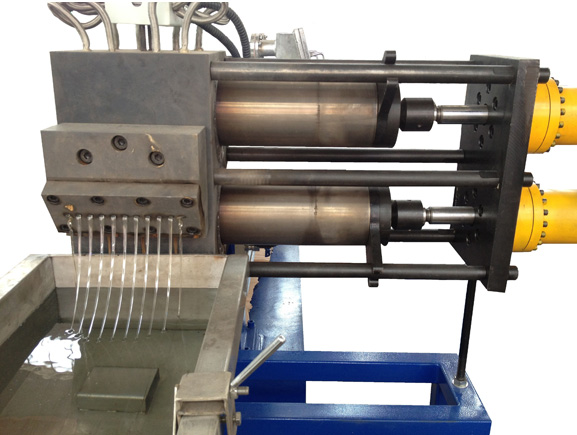

The machine has excellent mixing performance, good self-cleaning performance and flexible modular configuration characteristivs which make them suitable for processing different types of material.

Different kinds of side doser is used to feeder different kinds or types of material. There is also doser to weight the additives material to make up a prescription.