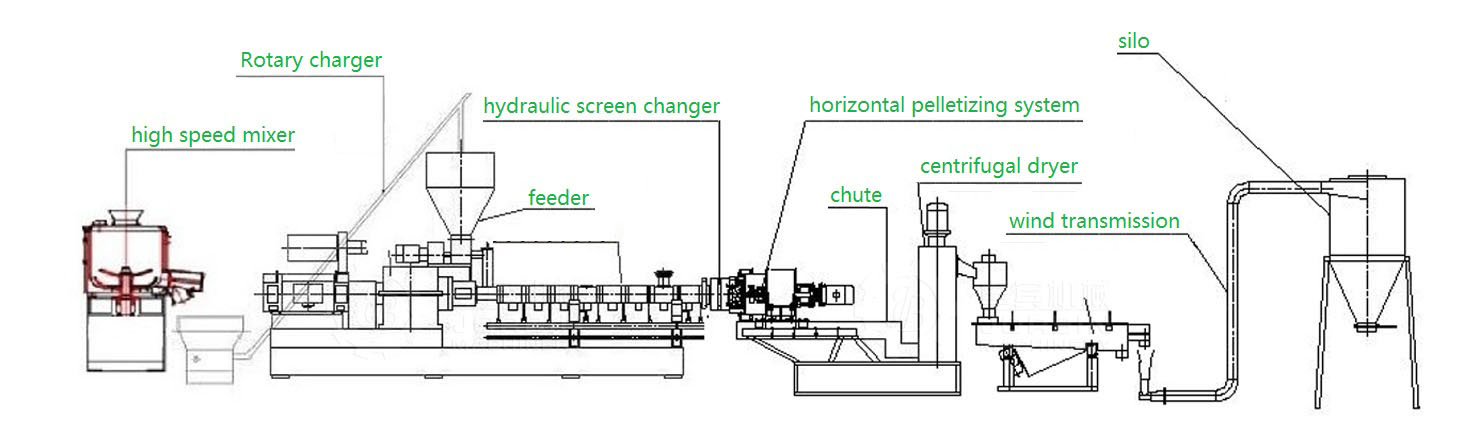

Twin screw/double screw compounding extruder is specially designed for compounding PE (LLDPE, LDPE, HDPE), PP, PA6, PA66,PC, PEK,TPE and Copolymers such as SBS,Color batches,Filler modified resin and additives ( UV protection Materials, Modified, EVA, black carbon granule, flame-retardant granule.

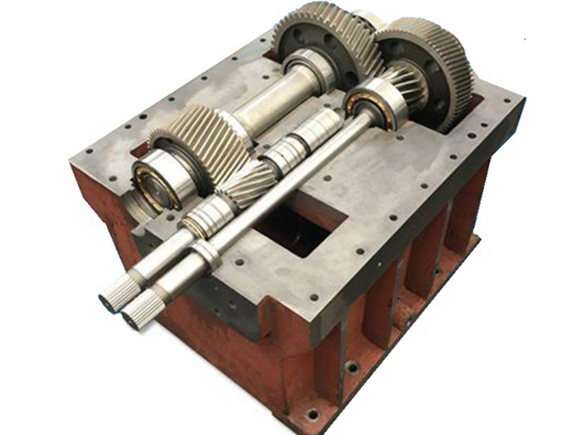

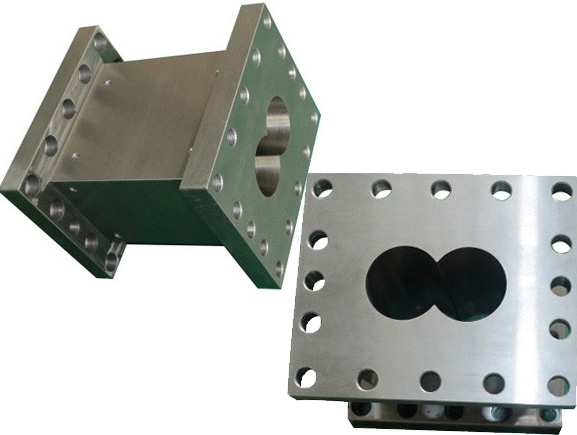

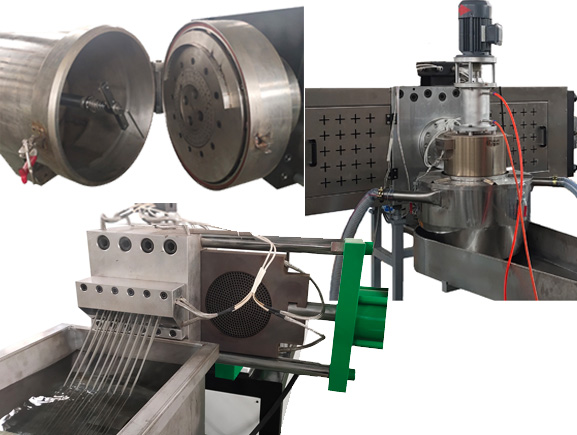

The machine has excellent mixing performance, good self-cleaning performance and flexible modular configuration characteristivs which make them suitable for processing different types of material.

Different kinds of side doser is used to feeder different kinds or types of material. There is also doser to weight the additives material to make up a prescription.