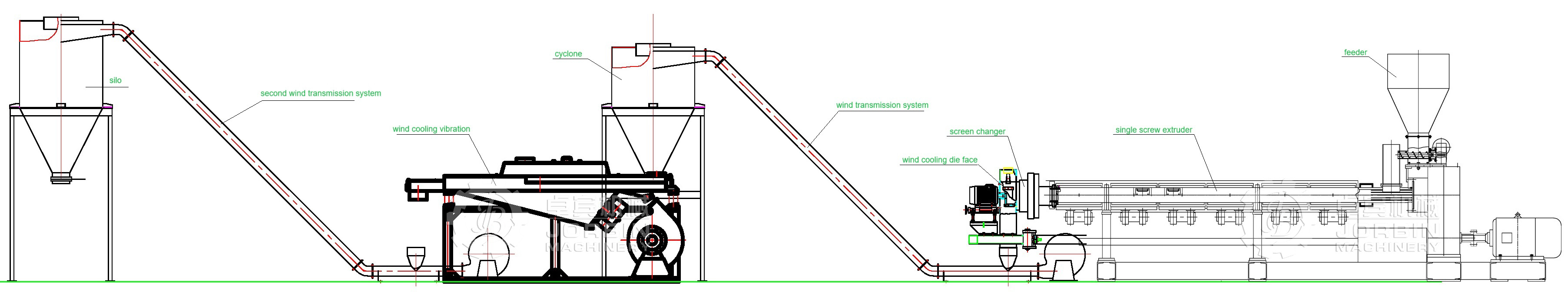

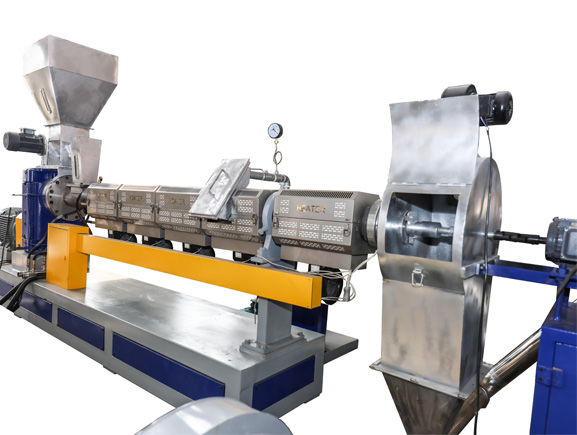

PVC EVA recycling extrusion granulator with Single Screw, it is mainly used for processing rigid crushed PVC EVA flakes, such as cable, boots, car bumper and son on.

If the material is too dirty, we can use a washing machine to wash the material first, and the washing machine include crusher,washing and dryer, so that the clean plastic flakes need to be granuated by extruders. Then the finally hese granules can be for further production and processing of plastics into finished products, which can be by blowing, injection and calendering. The total granulation line combines quantitative feeding, high efficiency double extruder,different types of filter and different types of pelletizer by modular design. All the machines are customized.

The machine is wind cooling die face cutting system, because PVC is not good to cool by water, so cooling by wind is better, and the cyclone, wind cooling vibration can cool the material.