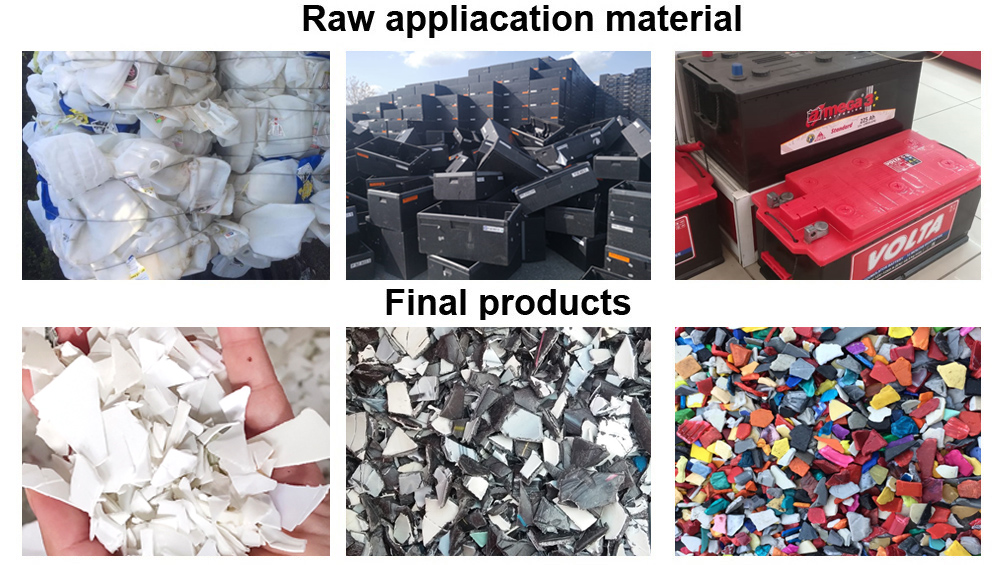

The machine is special for recycle HDPE LDPE LLDPE PP PET water bottles, milk or oil bottles , basket and so on. Waste packing material and film plastics also can be treated step by step. You can put dirty bottles, pipes or film/bags direct to wash it, after washing it you can use them to pelletize or injection or do other things.

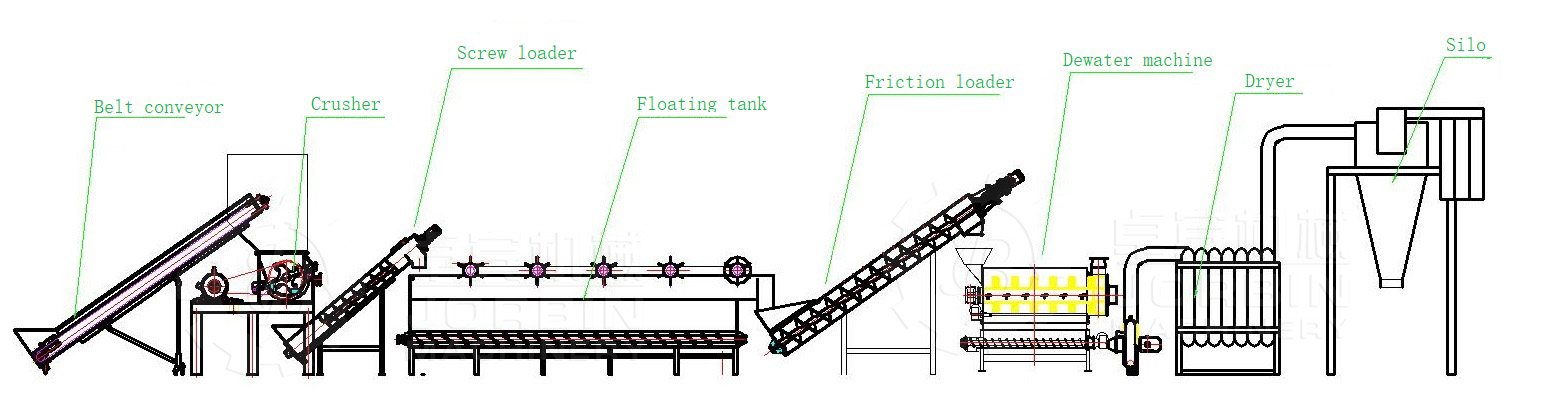

1. The whole line flowing is : conveyer belt - crusher - Screw loader - floating - screw loader - frication machine - Screw loader - dewater - screw loader - hot pipe dryer.

2. The capacity can be supplized accroding to your requrement, such as : 300kg/h, 500kg/h, 800kg/h, 1000kg/h,1500kg/h, 2000kg/h

3. How many parts do you need is according to your require.such as floating ,you can use one set or two sets, and also three sets, this is up to how dirty of your raw material. Of courese, you can show us your raw material, we can design the much correct machine for you according to the material situation.

4. You can choose full automatic or half-automatic line.

5. We have SGS certifcation, past CE certifcation.

6. After drying the water content can reach 5-8% (according to the thickness of film)